- PRODUCTS

- MODEL LIST

- APPLICATIONS

- SUPPORT

- SALES/SERVICE

- BLOG

- ABOUT

Guide to CTDs

A CTD measures Conductivity, Temperature, and Depth.

D (Depth): Despite having depth in the name, all CTDs actually measure pressure, which is not quite the same thing. The relationship between pressure and depth is a complex one involving water density and compressibility as well as the strength of the local gravity field (a function of the latitude). In oceanography, pressure in a body of water is measured in decibars; the pressure at the surface of the water is 0 decibars. As an approximation, each 1 meter depth of water (3.28 feet) is equivalent to 1 decibar (for example, the pressure is 10 decibars at 10 meters depth).

T (Temperature): Temperature is measured in ITS-90 degrees Celsius (°C). ITS-90 is an instrument calibration standard agreed to by a number of scientists in 1990, which provides for comparison and compatibility of temperature measurements internationally (so 25 °C in the U.S. is the same as 25 °C in China, etc.). For the ocean, temperatures typically range from -2 to 35 °C (28.4 to 95.0 °F).

C (Conductivity): Finally, we get to Conductivity, the parameter you may be least familiar with. Conductivity is a measure of a material’s ability to conduct an electrical current. For electrical circuits, metals have high conductivity, while glass has low conductivity. Water with a large amount of dissolved salts has high conductivity, while fresh water has low conductivity. Temperature also affects conductivity: warm water has high conductivity, while cold water has low conductivity. The units for conductivity are Siemens/meter (S/m). For water ranging from freshwater to seawater, conductivity typically ranges from 0 to 7.5 S/m.

Why are we interested in conductivity?

If we measure conductivity, temperature, and pressure, we can calculate the amount of dissolved salts in the water – the salinity. The units for salinity are PSU (Practical Salinity Unit); a typical value in the ocean is 35 PSU. Once we know salinity, we can calculate many other parameters, such as density and sound velocity.

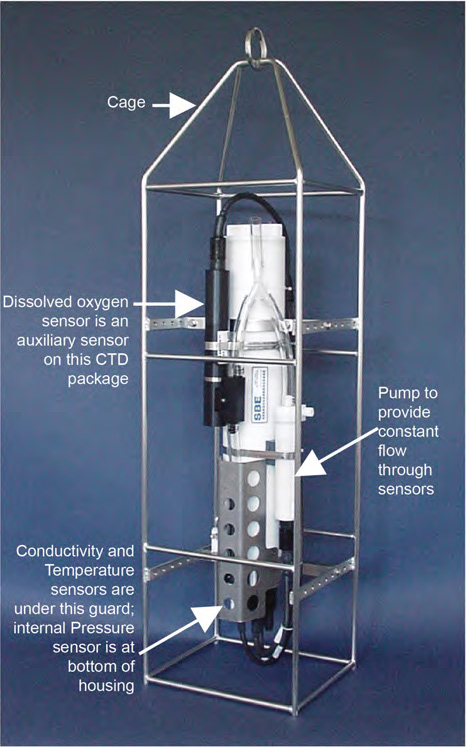

The term CTD is often used to describe a package that includes the actual CTD as well as auxiliary sensors to measure other parameters (such as dissolved oxygen, pH, turbidity, fluorescence, oil, PAR, nitrates, altimeter, etc.).

What can we do with data from a CTD?

- Estimate deep-ocean currents based on density variations

- Look for sharp density changes to investigate the interesting chemical and biological processes that go on there

- Look for the boundaries of surface ocean currents

- Look for the movements of different water masses near shore that indicate upwelling or currents that move sediment along the shore

- Calculate sound velocity at various depths, to refine acoustic investigation of the ocean bottom or acoustic investigation of objects in the water (such as submarines or torpedoes)

- Discover an area of very low oxygen, which can have a major impact on fish

Profiling CTDs

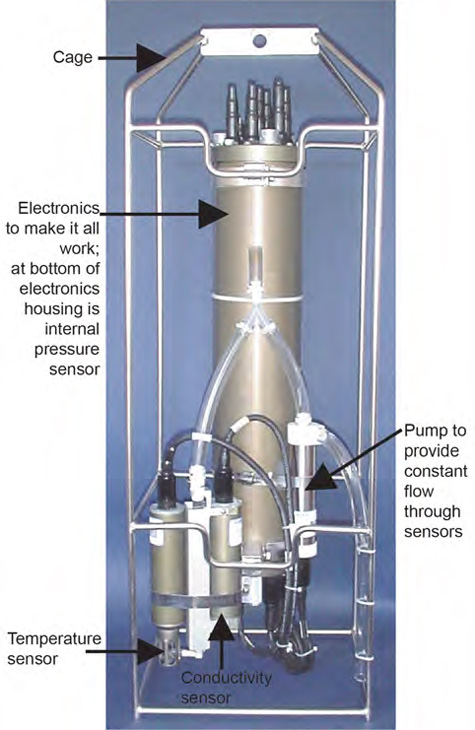

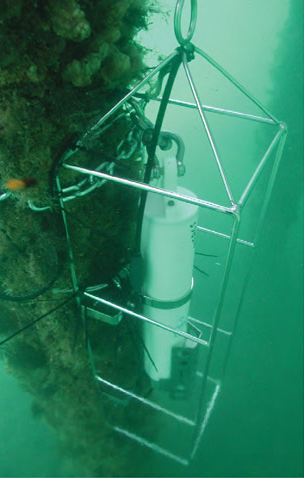

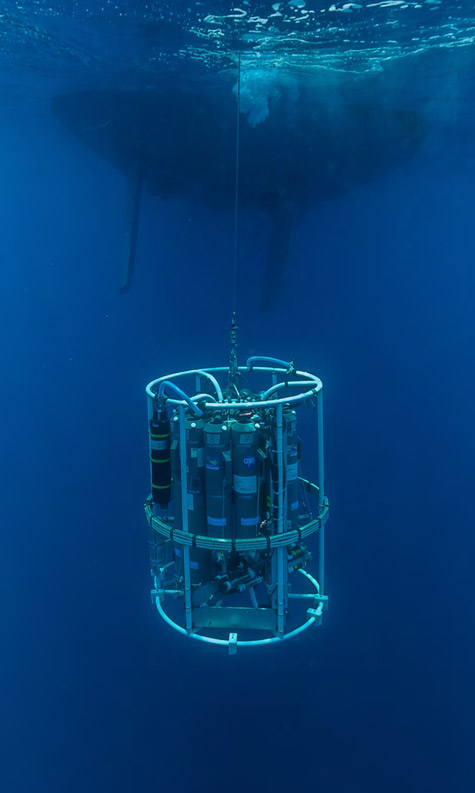

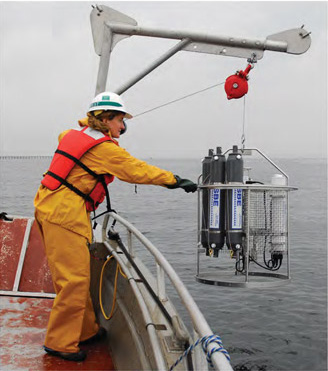

A profiling CTD measures water parameters as it travels vertically through the water, typically lowered over the side of a ship with a winch or by hand to take measurements of a column of water. A profiling CTD package often is placed inside a cage, to protect the package from collision with the side of the ship. A profiling CTD package can also include a water sampler that collects discrete samples for later analysis in the lab.

More profiling terminology:

Real-time profiling means that you are viewing and storing data on your computer atessentially the same time that the measurement is being made at the end of the sea cable. The essentially part is because there is some time involved in packaging the bits up and sending them up the cable and onto your computer. Real-time profiling requires a winch (if the package is too heavy to lower by hand) and sea cable with an internal conductor, so that it can transmit the data from the instrument; these systems often also provide power to the CTD. If transmitting data and power over long distances, a Deck Unit is usually required as the interface to the CTD; it sends power to the CTD, interprets the data from the CTD, and passes the data to a computer.Internally recorded profiling means that the measurements are stored in memory inside the instrument and are transferred to your computer and viewedafter the equipment is back on deck. The ship still needs a winch (if the package is too heavy to lower by hand) and cable, but the cable is not required to have an internal conductor.- A

cast is one down-and-up cycle of the CTD. Each cast consists of a downcast and upcast. Because of the way the CTD and other equipment are configured on the package, the data from the downcast is usually more accurate.

SBE 9plus

CTD System for profiling from a ship: SBE 9

SBE 19plus V2 SeaCAT

Smaller, less expensive system for profiling from a ship: SBE 19

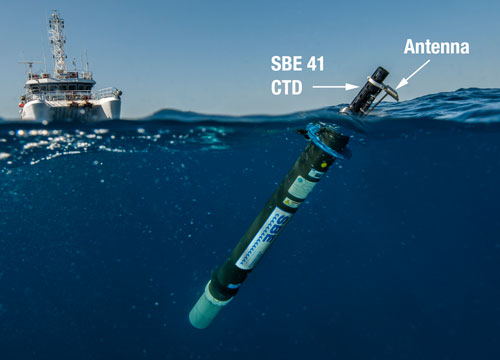

Profiling CTDs can also be deployed in many ways other than being lowered and raised from a ship. They can be integrated with an autonomous vehicle like an ROV (Remotely Operated Vehicle), a glider, or an Argo float that drifts with the currents. The type of vehicle and characteristics of its use dictate the CTD design that will provide the best data; CTDs are not one-size-fits-all instruments, if you are interested in good data.

Because some of these CTDs are deployed for an extended period of time (3 to 5 years for an Argo float!), they are subject to

SBE 16plus SeaCAT

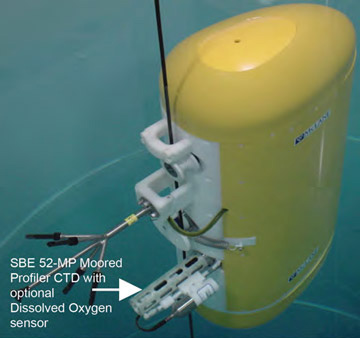

A moored CTD measures water parameters in one location, over an extended period of time, providing a time series of data that can reveal information about seasonal variations in the water, incursion of pollutants into the area (such as an oil spill), etc.

To reduce costs, the pressure sensor is occasionally omitted, because the deployment depth (and therefore pressure) is approximately known. However, the pressure sensor is required when deployed on a fixed location like a pier (shown at left), where tidal fluctuations can cause large changes in pressure. And for any deployment, the pressure sensor is required for the most accurate salinity data. Similar to profiling CTDs, some moored CTDs can be integrated with sensors for measuring additional parameters (dissolved oxygen, turbidity, fluorescence, etc.)

Because moored CTDs are in place for an extended period of time, they are subject to bio-fouling – the growth of marine organisms on and inside the sensors. Bio-fouling is more aggressive in warm surface waters. Sea-Bird moored CTDs use EPAapproved anti-foulant devices to keep the inside of the sensors clean, so that fouling will not affect the measurements.

Effective anti-fouling techniques for auxiliary optical sensors include the use of copper, plus a wiper to clear the optics prior to each sample.

Photo: An SBE 16plus SeaCAT CTD after recovery. While the outside of the CTD is encrusted, the intake to the Conductivity sensor is clear, indicating that the inside of the cell is clear as well.

The face of each WET Labs ECO sensor is also clear, because the copper faceplate and bio-wipers are preventing build-up of fouling.

A thermosalinograph is basically a shipboard CTD without a pressure sensor. Thermosalinographs are used to collect information about the sea surface, typically in flow-through systems operating continuously throughout a cruise. Thermosalinographs are usually installed inside and near to the hull of a ship in order to make measurements on uncontaminated seawater. Thermosalinograph data can be used to calculate salinity, density, sound velocity, and other parameters of interest. You can often plumb other types of sensors into the system for a variety of other measurements.

Similar to moored CTDs, thermosalinographs are also subject to

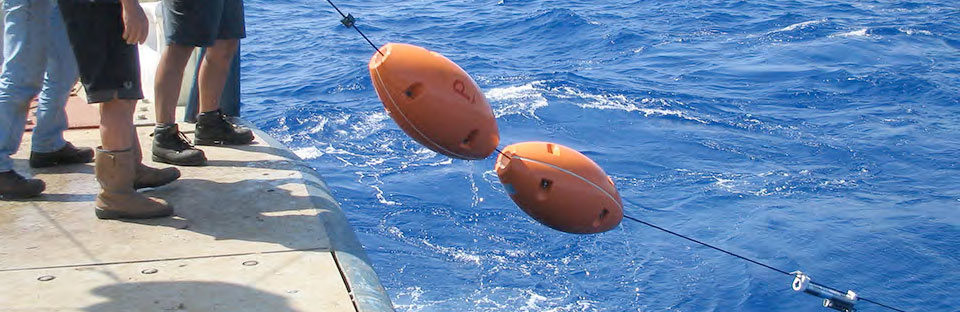

Water sampling equipment usually consists of:

- Water sample bottles with spring-loaded top and bottom end caps

- Trigger mechanism and electronics

- Lanyards that connect the bottle end caps to the trigger mechanism

- Frame that holds the bottles and trigger mechanism and electronics, and also protects the package from collision with the side of the ship

The bottle end caps are connected by a tensioning device, either an elastic cord going through the inside of the bottle or a spring on the outside of the bottle. The water sampler is typically deployed with all the bottle end caps held in the open position by the lanyards, allowing water to freely flush through the bottles. When the trigger mechanism

Water samplers are built in many sizes, and the bottles are also available in many sizes. Sea-Bird builds water samplers that can hold bottles as small as 1.7 liters each, up to as large as 30 liters each (0.4 to 7.9 gallons). These samplers can hold as few as 3 bottles, and as many as 36 bottles.

More water sampling terminology:

Real-time water sampling means that someone on deck is monitoring the data coming up from the CTD (real-time profiling ). The person monitoring the CTD data makes decisions about when to close each bottle, based on the data they are viewing and the scientific goals of the study. For example, they may want to take water samples in an area where the salinity has changed suddenly, indicating a current. And they may want to take samples in areas where there is very little change in any of the measured parameters, providing good samples to analyze in the laboratory to compare to the CTD measurements as a check of the accuracy of the instruments on the CTD package. Real-time water sampling requires a winch, a conducting cable, and a Deck Unit.Autonomous water sampling means that you have preprogrammed the water sampler to close bottles. Depending on the equipment, you can program it to close bottles at specific pressures (depths), when the CTD remains stationary for a specific period of time, or even at specific times. The water sampler receives pressure information from the CTD (remember, the CTD is measuring pressure), and uses that data to evaluate when the appropriate pressure has been reached, or when the package has been stationary. The water sampling equipment stores data internally, providing information to allow you to match up the water sample with the data measured by the CTD at the same time. The data from the water sampling equipment and the data from the CTD are transferred to your computer and viewed after the equipment is on deck. The ship still needs a winch and cable, but the sea cable does not need to be a conducting cable.

SBE 55 ECO Water Sampler

- Glossary of Oceanographic Terms

- Conductivity Sensors for Moored and Autonomous Operation

- Application Note 38: Fundamentals of the TC Duct and Pump-Controlled Flow Used on Sea-Bird CTDs

- Application Note 82: Guide to Specifying a CTD

- Application Note 6: Determination of Sound Velocity from CTD Data

- What is Wrong with my Data? Considerations for CTD Spatial and Temporal Resolutions on Moving Platform

- Sea-Bird training materials from our 4-day course